reduce costs and increase functionality

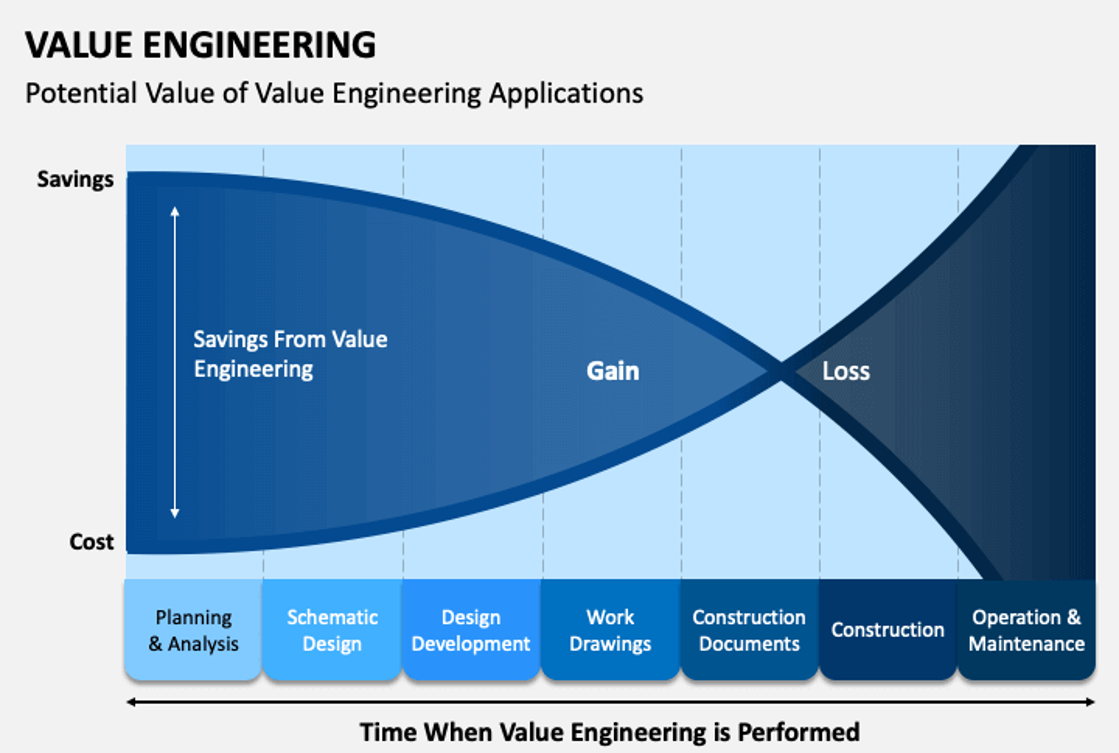

Throughout a project’s planning, design, construction, and operations and maintenance phases, Value engineering is employed as a means of balancing a project’s scope and expectations of quality and budget.

PMIS team will monitor the Project value from the inception stages of the project and as an on-going process in order to reduce the risk of potentially costly design modifications and fundamental system changes.

Utilizing a systematic approach, which identifies and provides the required functions of a project at the lowest possible cost, and keeping the design intent unchanged, will result in the following:

- Savings on construction costs.

- Lower life cycle costs.

- Improved operational performance.

- Reduced maintenance costs.

- Identification of risks and mitigation strategies.

PMIS offers VE Workshops that are conducted using a multi-disciplined team approach, which include professionals such as architectural, structural, civil, mechanical, and electrical engineers as deemed relevant for the disciplines being studied. This structure allows for the involvement of the Client, A/E and Construction Manager. The team approach used for VE studies are comprised of three specific phases:

- Pre-Study Preparation Phase

- VE Study Phase

- Post VE Study Phase